From project to product:

behind the scenes of SIT-SIT furniture creation

About us

SIT-SIT has been engaged in the production of bean bags filled with polystyrene granules since 2006. As a brand, we are constantly evolving, following the trends, and investing in design. In 2020, we expanded our range to include outdoor bean bags, and in 2021, we introduced elegant modular outdoor sofas.

As a company, we have our own, regularly audited production facility, and the knowledge and experience of our sewing team allow us to flexibly adapt to the ideas and requirements of our customers. Our in-house production not only ensures supply chain continuity but also enables smooth order fulfillment and maintains high product quality.

How are SIT-SIT products created?

Design

1

It all begins with a vision.

Our sofas and bean bags embark on their journey from the moment designers transform their extraordinary ideas into concrete plans. Every detail is meticulously considered, from the unique design to the selection of materials, ensuring unforgettable comfort, style, and durability in our products.

Prototyping workshop

2

When the vision takes on a tangible form, we move to our prototyping workshop, where plans transform into reality. At this stage, the prototype is created, and any necessary adjustments are precisely implemented to ensure everything harmonizes perfectly.

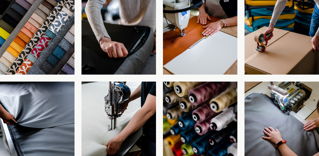

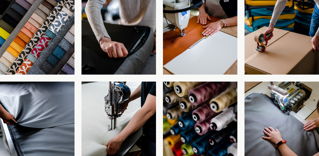

Sewing workshop

3

After the prototype is approved, we move to the sewing workshop, where every detail is precisely cut and carefully stitched. The high quality of materials and meticulous attention to detail ensure the durability and unique aesthetics of our products.

Sofas

Bean bags

After the sewing process is completed, our unique bean bag covers move on to the next stage of production, where we impart them with exceptional softness and comfort. In this process, the covers are carefully filled with eco-friendly regrind, ensuring that our bean bags are incredibly comfortable.

After the covers are stitched, they are applied to thick foam cushions in the next stage of production. The frames supporting our sofas are made from powder-coated stainless steel, to which incredibly durable support straps are attached. All of this ensures that our sofas not only impress with their design but also meet the highest standards of comfort and durability.

Quality control

4

Safety and customer satisfaction are our top priorities. That's why each product undergoes a rigorous quality control process. Our team of specialists examines every aspect, ensuring that our sofas and bean bags meet the highest standards of quality, safety, comfort, and durability.

Logistics

5

After completing the quality control process, our finished products move on to the storage and delivery stage.

We carefully plan and organize transportation. Thanks to precise logistics, we ensure fast and secure deliveries, ensuring that our products reach you in impeccable condition.

That's how SIT-SIT furniture is born – in the magical world of design where every detail matters, and each piece of furniture has its unique story to tell.